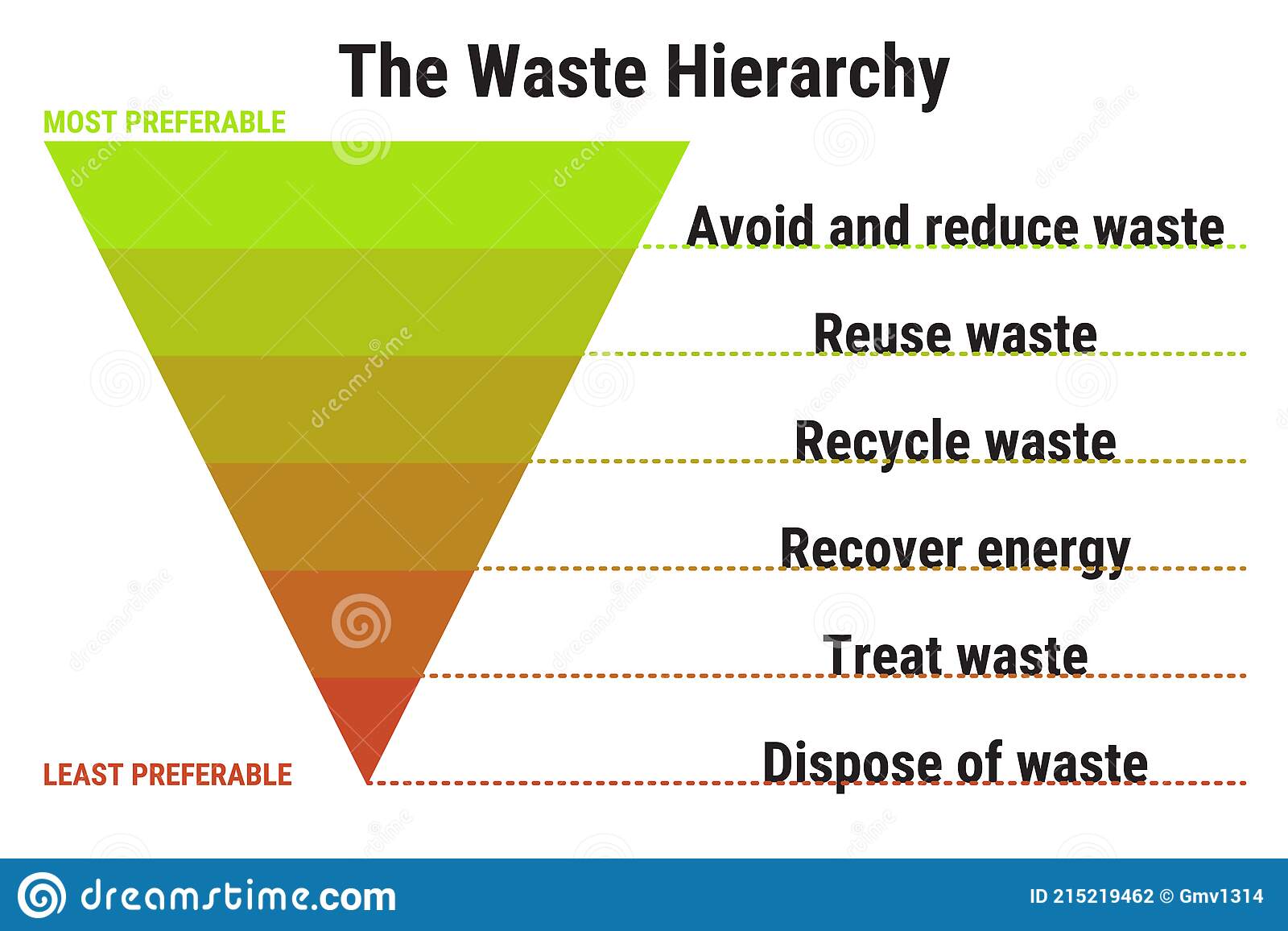

The waste hierarchy can be used to evaluate environmental activities. It ranks environmental actions according to their most and least benefits, and determines the priorities of programs based on sustainability. The waste hierarchy provides valuable tools for waste management. It can be used for many aspects related to environmental management including production of food and water as well as energy.

Prevent

Prevent waste is a hierarchy that focuses on eliminating waste at its source. Avoiding products with excessive packaging is one way to reduce waste. This is the first stage in reducing waste. Understanding how waste materials are created and packaged will help you understand how they are disposed of. Additionally, businesses should reduce their consumption perishable goods and prepare waste for reuse.

Companies and consumers can benefit from the waste hierarchy by encouraging circular economies and sustainability. It will reduce waste generated, prevent them from producing unnecessary products, and encourage green technology development to reduce greenhouse gas emissions.

Recycle

The waste hierarchy, an environmental evaluation tool, ranks different actions according to their environmental benefit. It's used to identify preferred program priorities. It ranks actions by their favorability. The waste hierarchy helps to identify the most effective and least harmful ways to achieve desired results. The hierarchy is a powerful tool that can help you determine the most effective program practices.

The prevention stage is the first. It focuses on reducing waste generation. Next, the reuse stage focuses on recovering valuable material. The last step, disposal is the most hazardous.

Get rid of

There are many ways to dispose off waste. However, the best way is the waste hierarchy. This system allows you reuse and recycle materials and also feeds waste back into the economy. Some materials may not be recyclable or re-usable, and will need special treatment before disposal.

A waste hierarchy helps decision-makers determine which waste management methods will have the best impact on the environment. There are five phases to the waste hierarchy. The first stage is prevention. Next, there are recovery, disposal, and preparation.

Prevention

The Prevention of Waste Hierarchy (Potential Waste Hierarchy) is key to reducing waste and protecting our environment. The hierarchy includes different levels that have different impacts on the environment. Reduction is the first level. It focuses on reducing waste and avoiding material that has negative environmental impacts. Prevention refers to streamlining the design process, encouraging longer product usage, and encouraging better environmental practices. Prevention also involves research and development in cleaner technologies.

The prevention of waste hierarchy identifies different methods for reducing waste and ensuring its safe and effective management. Currently, it is included in recycling regulations and solid waste management plans. It also includes recovery prior to disposal. Unfortunately, many organizations are too focused on the fourth R rather than the first two. This leads to costly systems that either don't reduce waste nor reduce environmental impact. Zero Waste International Alliance created the only internationally peer-reviewed Zero Waste Hierarchy. It promotes the first three methods to reduce waste.

FAQ

How can a manager motivate his/her staff?

Motivation refers to the desire to perform well.

You can get motivated by doing something enjoyable.

You can also get motivated by seeing your contribution to the success or the improvement of the organization.

For example: If you want to be a doctor, you might find it more motivating seeing patients than reading medical books all day.

Another type of motivation comes from within.

One example is a strong sense that you are responsible for helping others.

Maybe you like working hard.

If you don't feel motivated, ask yourself why.

Then try to think about ways to change your situation to be more motivated.

What role should a manager play within a company

Different industries have different roles for managers.

In general, a manager controls the day-to-day operations of a company.

He/she will ensure that the company fulfills its financial obligations.

He/she is responsible for ensuring that employees comply with all regulations and follow quality standards.

He/she is responsible for the development of new products and services, as well as overseeing marketing campaigns.

What are the five management process?

These five stages are: planning, execution monitoring, review and evaluation.

Setting goals for the future is part of planning. Planning includes setting goals for the future.

Execution is the actual execution of the plans. They must be followed by all parties.

Monitoring allows you to monitor your progress towards achieving your goals. Regular reviews of performance against budgets and targets should be part of this process.

Every year, there are reviews. They are a chance to see if everything went smoothly during the year. If not there are changes that can be made to improve the performance next year.

After the annual review is complete, evaluations are conducted. It helps you identify the successes and failures. It also provides feedback on the performance of people.

How can we create a culture of success in our company?

A positive company culture creates a sense of belonging and respect in its people.

It's founded on three principal principles:

-

Everyone has something to contribute

-

Fair treatment of people is the goal

-

It is possible to have mutual respect between groups and individuals

These values are reflected in the way people behave. They will treat others with kindness and consideration.

They will listen respectfully to the opinions of others.

These people will inspire others to share thoughts and feelings.

The company culture promotes collaboration and open communication.

People feel comfortable expressing their opinions freely without fear of reprisal.

They understand that mistakes can be forgiven as long as they're dealt with honestly.

Finally, the company culture encourages honesty as well as integrity.

Everyone is aware that truth must be told.

Everyone understands there are rules that they must follow.

And no one expects special treatment or favors.

What is the meaning of "project management?"

That is the management of all activities associated with a project.

Our services include the definition of the scope, identifying requirements, preparing a budget, organizing project teams, scheduling work, monitoring progress and evaluating the results before closing the project.

What is Kaizen?

Kaizen, a Japanese term that means "continuous improvement," is a philosophy that encourages employees and other workers to continuously improve their work environment.

Kaizen is a belief that everyone should have the ability to do their job well.

What are your main management skills

Managerial skills are crucial for every business owner, regardless of whether they run a small store in their locality or a large corporation. They are the ability to manage people and finances, space, money, and other factors.

Managerial skills are required when setting goals and objectives and planning strategies, leading employees, motivating them, solving problems, creating policies, procedures, or managing change.

As you can see, there are many managerial responsibilities!

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

External Links

How To

How can you implement the Kaizen technique?

Kaizen means continuous improvement. Kaizen is a Japanese concept that encourages constant improvement by small incremental changes. It is a process where people come together to improve their processes.

Kaizen is one of Lean Manufacturing's most efficient methods. Kaizen is a concept where employees in charge of the production line are required to spot problems during the manufacturing process before they become major issues. This will increase the quality and decrease the cost of the products.

Kaizen is about making everyone aware of the world around them. So that there is no problem, you should immediately correct it if something goes wrong. Report any problem you see at work to your manager.

Kaizen is based on a few principles. We always start from the end product and move toward the beginning. If we want to improve our factory for example, we start by fixing the machines that make the final product. Next, we fix the machines which produce components. We then fix the workers that work with those machines.

This is known as "kaizen", because it emphasizes improving each step. After we're done with the factory, it's time to go back and fix the problem.

You need to know how to measure the effectiveness of kaizen within your business. There are several ways to determine whether kaizen is working well. One method is to inspect the finished products for defects. Another way to find out how productive your company has been since you implemented kaizen is to measure the increase in productivity.

A good way to determine whether kaizen has been implemented is to ask why. You were trying to save money or obey the law? Did you really think that it would help you achieve success?

Suppose you answered yes to any of these questions, congratulations! You are ready to start kaizen.